Discover the Benefits of a Stainless Steel Gully Grid in Latest News Content

By:Admin

Introduction:

Drainage systems play a crucial role in maintaining the cleanliness and functionality of urban environments. However, traditional gully grids often prove ineffective in managing heavy rainfall, leading to flooding and other related issues. In response to this challenge, {Company Name}, a leading innovator in the field, has developed a groundbreaking stainless steel gully grid system that promises to revolutionize drainage systems across industries and communities.

1. The Limitations of Traditional Gully Grids:

Traditional gully grids used in drainage systems are typically made of cast iron or other materials that are prone to corrosion and regular wear and tear. As a result, they often fail to effectively filter debris, causing blockages and increasing the risk of flooding. Moreover, these grids require frequent maintenance and replacement, leading to substantial ongoing costs.

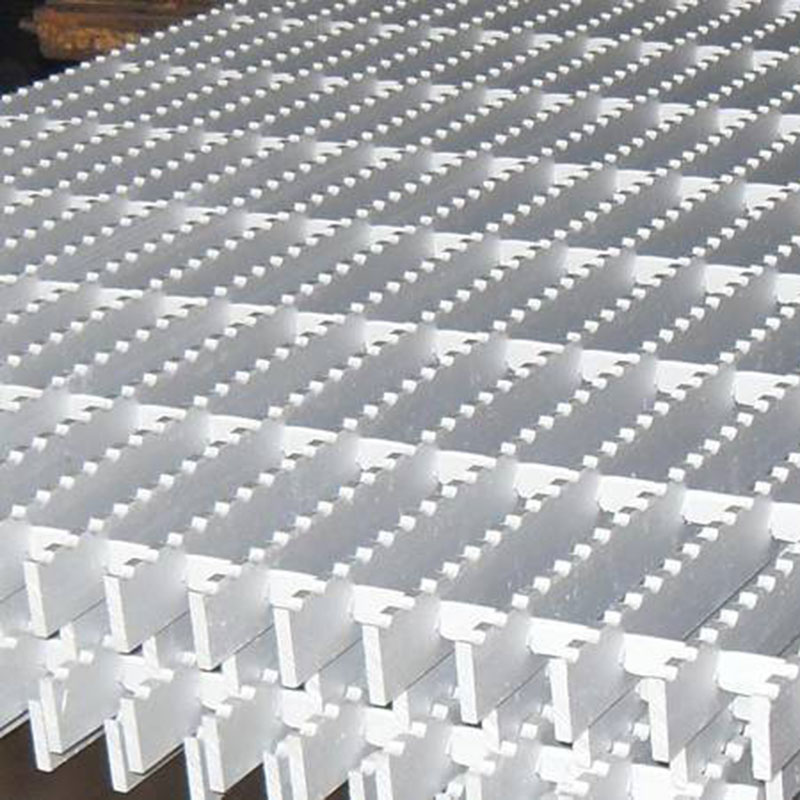

2. Introducing the Stainless Steel Gully Grid - A Game-Changing Solution:

{Company Name} has addressed these challenges by leveraging its expertise in material engineering and developing highly durable and efficient stainless steel gully grids. Made from corrosion-resistant steel alloy, these innovative grids are designed to withstand harsh weather conditions and heavy loads, ensuring long-lasting performance.

a. Enhanced Filtering Mechanism:

Unlike traditional grids, the stainless steel gully grids feature an advanced filtering mechanism that efficiently separates larger debris from wastewater. This prevents blockages and allows water to flow smoothly through the drainage system.

b. Environmentally Friendly Design:

The company's stainless steel gully grids are designed with sustainability in mind. The grids are manufactured using recycled stainless steel and are fully recyclable, reducing environmental impact. Additionally, their innovative design minimizes water pollutant discharge, making them an eco-friendly alternative to traditional grids.

c. Cost-Effective Solution:

Due to their exceptional durability, the stainless steel gully grids significantly reduce maintenance and replacement costs. Their resistance to corrosion and wear ensures a longer lifespan, resulting in substantial savings for both municipalities and private entities.

d. Easy Installation and Adaptability:

{Company Name}'s gully grids are designed for seamless installation, making them suitable for a wide range of drainage systems. Their standardized sizing and compatibility with existing infrastructure allow for convenient replacements or upgrades without costly modifications.

3. Multiple Applications in Various Industries:

The versatility of {Company Name}'s stainless steel gully grid system enables its use in multiple industries, including:

a. Urban Development:

In urban areas, these grids can be installed on city streets, parking lots, and sidewalks, effectively managing stormwater and minimizing disruptions caused by heavy rainfall. Their reliability also enhances the overall aesthetics and safety of urban environments.

b. Industrial Facilities:

Industrial sites, such as factories and warehouses, often face significant drainage challenges due to the presence of heavy machinery and large-scale operations. The stainless steel gully grid system provides an effective solution by efficiently handling excessive water runoff, mitigating the risk of flooding, and ensuring the smooth functioning of these facilities.

c. Airports and Ports:

Transportation hubs like airports and ports require advanced drainage systems to handle high volumes of water. The stainless steel gully grids are designed to withstand heavy loads and allow the efficient flow of water, preventing delays and ensuring the safety of passengers and cargo.

4. Conclusion

With their superior durability, enhanced filtering capabilities, and eco-friendly design, {Company Name}'s stainless steel gully grids are set to revolutionize drainage systems. This innovative solution promises to prevent flooding, reduce maintenance costs, and contribute to the sustainability of our urban environments. As cities and industries worldwide adopt this groundbreaking technology, our drainage systems will become more reliable and efficient, ensuring a better future for all.

Company News & Blog

Discover the Versatility and Durability of Metal Grating Panels

Title: Metal Grating Panels Revolutionize Industrial Flooring: A Game-changer by Company XYZIntroduction:With industries and infrastructure constantly evolving, the demand for durable, efficient, and safe flooring solutions has never been higher. Catering to this growing need, Company XYZ has recently introduced a series of state-of-the-art Metal Grating Panels, providing an innovative solution to various industrial applications. This game-changing product reaches new heights in both functionality and reliability, offering a safer and more efficient flooring alternative. This article will explore the key features and benefits offered by these Metal Grating Panels by Company XYZ, revolutionizing the industrial flooring industry.Section 1: Overview and Key Features of Metal Grating PanelsCompany XYZ's Metal Grating Panels are engineered using advanced materials and cutting-edge manufacturing techniques. These panels are meticulously designed to withstand heavy loads, corrosive environments, and extreme weather conditions. The grating panels consist of interlocking metal bars that provide optimal traction and prevent slips, making them ideal for high-risk industrial environments. These robust panels also boast incredible load-bearing capacity, making them suitable for heavy machinery and extensive foot traffic.Section 2: Enhanced Safety MeasuresSafety is a paramount concern in industrial settings. Metal Grating Panels by Company XYZ address this concern by offering several safety features that prioritize the well-being of workers. The interlocking design of the panels ensures superior stability, reducing the risk of accidents caused by loose or damaged flooring. Additionally, the innovative surface pattern enhances traction, minimizing slipping hazards, and preventing accidents. Furthermore, Metal Grating Panels are fire-resistant, an essential feature in industries prone to high heat or combustion risks. This added safety measure significantly lowers the probability of fire-related incidents, providing peace of mind to the workforce.Section 3: Versatility and Customization OptionsCompany XYZ's Metal Grating Panels are highly versatile and can be customized to suit specific project requirements. Available in various sizes, shapes, and materials, these panels can be tailored to fit any industrial space. Whether it is an offshore platform, a manufacturing facility, or a wastewater treatment plant, the Metal Grating Panels offer a reliable flooring solution that can be adapted to any industry.Moreover, the panels are available in a range of finishes, including galvanized steel, stainless steel, and aluminum, offering exceptional durability and resistance to corrosion. This versatility ensures that the panels can withstand harsh environments, making them suitable for indoor and outdoor applications.Section 4: Environmental Sustainability In line with Company XYZ's commitment to sustainability, the Metal Grating Panels are eco-friendly. The use of recyclable materials and responsible production processes ensures that these panels have a minimal environmental footprint. Additionally, their long lifespan and resistance to wear and tear reduce the need for frequent replacements, further contributing to sustainable practices.Section 5: Economic BenefitsMetal Grating Panels by Company XYZ also bring significant economic benefits to industrial operations. The panels' robust durability and low maintenance requirements lead to reduced lifetime costs, as they eliminate the need for frequent repairs or replacements associated with traditional flooring solutions. Additionally, the increased safety provided by these panels translates to lower insurance costs and minimized downtime due to workplace accidents, making them a valuable investment for any industrial facility.Conclusion:Company XYZ's Metal Grating Panels represent a game-changing innovation in the industrial flooring industry. The advanced features, enhanced safety measures, customization options, environmental sustainability, and economic benefits offered by these panels make them an indispensable flooring solution in a wide range of industrial sectors. With Metal Grating Panels by Company XYZ, industries can experience improved safety standards, increased efficiency, and long-term cost savings, solidifying their position as an industry leader.

Serrated Bar Grate: The Essential Guide to Understanding and Choosing the Right Grating Solution

Title: Innovative Serrated Bar Grate - A Game-Changer in the Construction IndustryIntroduction:In an ever-evolving construction landscape, companies consistently strive to develop groundbreaking solutions that enhance safety, efficiency, and durability. One such advancement making waves in the industry is the Serrated Bar Grate, a revolutionary product that embodies these attributes to revolutionize construction practices. Developed by an esteemed company [], this state-of-the-art invention promises to reshape the industry's norm and redefine safety standards, while also streamlining project completion. Let's delve deeper into the features and capabilities of this game-changing product.Unraveling the Serrated Bar Grate:The Serrated Bar Grate represents a breakthrough in construction materials due to its unique design and exceptional properties. Made from high-quality steel, this innovative grate combines an interlocking series of serrated bars with a framework, ensuring unrivaled strength and durability. Not only does it exceed established safety standards, but it also acts as a seamless bridge between the conventional walkway grating and heavy-duty bar grating, serving a wide range of applications with ease.Safety Redefined:By incorporating a serrated surface, this grate provides an exceptional anti-slip feature, maximizing worker safety and reducing the risk of accidents, even in adverse weather conditions. The serrated texture ensures superior grip, allowing for secure movement across platforms, walkways, and bridges. Furthermore, its exceptional load-bearing capabilities offer reliable support, particularly in high-traffic areas or heavy machinery application scenarios.Versatility in Application:The Serrated Bar Grate caters to diverse construction needs, with its strength and versatility making it suitable for an array of projects. From industrial plants, wastewater treatment plants, and refineries to power plants, chemical processing facilities, and offshore oil rigs, this grate proves invaluable in various industries. Whether it serves as an access platform, catwalk, or mezzanine flooring, its reliable performance and adaptability make it a favorite choice for architects and engineers alike across the globe.Unmatched Durability:Not only does the Serrated Bar Grate excel in safety and versatility, but it also boasts unparalleled durability. Its robust construction ensures resistance to heavy loads, extreme temperatures, corrosion, and wear and tear, making it an ideal long-term solution. With its low maintenance requirements, it significantly reduces total cost ownership and enhances overall project efficiency. This durability leads to substantial savings for construction companies, reducing the need for frequent replacements and repairs.Installation Efficiency:In addition to its outstanding performance, the Serrated Bar Grate offers convenience during installation. Its modular design ensures ease of assembly, allowing for efficient installation at construction sites. The interlocking serrated bars fit seamlessly, eliminating the need for time-consuming welding or extensive adjustments. This not only expedites project completion but also minimizes disruptions and associated costs.Conclusion:The Serrated Bar Grate, brought to the construction industry by [], represents a game-changing innovation that redefines safety, efficiency, and durability. Its exceptional anti-slip properties, versatility, and unmatched durability make it a preferred choice for a wide range of applications. With its streamlined installation process, the Serrated Bar Grate promotes enhanced construction project efficiency and reduced maintenance costs. As construction companies strive for excellence, embracing this revolutionary product will undoubtedly mark a significant shift towards safer and more efficient construction practices.

Benefits and Applications of Smooth Bar Grating: A Comprehensive Guide

Title: Innovative Smooth Bar Grating Solution Revolutionizing Industrial ApplicationsIntroduction:In today's rapidly evolving industrial landscape, companies are constantly seeking innovative solutions to enhance efficiency, safety, and the overall effectiveness of their operations. One such cutting-edge solution that has garnered significant attention is Smooth Bar Grating, developed by a leading company in the field. This versatile product has revolutionized numerous industries, providing unparalleled durability, traction, and drainage capabilities.Paragraph 1:Smooth Bar Grating, designed and engineered by [Company Name], offers a unique alternative to traditional flooring systems in industrial settings. This innovative solution is constructed from a series of closely spaced parallel bars, providing a smooth and seamless walking surface. Unlike other industrial flooring options, Smooth Bar Grating creates a secure and stable platform on which workers can confidently navigate, reducing the risk of accidents and injuries.Paragraph 2:One of the key advantages of Smooth Bar Grating is its exceptional durability. Constructed using high-quality materials such as carbon steel, stainless steel, or aluminum, this grating solution can withstand heavy loads, extreme temperatures, and corrosive environments. These features make it an ideal choice for industries such as manufacturing, petrochemical, and wastewater treatment, where reliable and long-lasting flooring is essential.Paragraph 3:With its unique bar orientation and spacing, Smooth Bar Grating allows for efficient drainage, preventing the accumulation of liquids, debris, and foreign matter. The open design also facilitates proper ventilation, reducing the potential for corrosion and moisture buildup. These drainage and airflow properties make Smooth Bar Grating an excellent choice for industries that require a hygienic and clean environment, such as food processing and pharmaceutical manufacturing.Paragraph 4:In addition to its durability and drainage capabilities, Smooth Bar Grating also provides excellent traction. The closely spaced, flat bars offer superior grip, even in slippery conditions, ensuring the safety of workers traversing the grating surface. This enhanced traction feature is of utmost importance in industries where slip and fall accidents can have severe consequences, such as oil and gas refineries or power plants.Paragraph 5:Another notable advantage of Smooth Bar Grating is its versatility. It can be customized to meet specific requirements, including varying bar spacing and thickness, creating tailored solutions for different industries. This adaptability allows for seamless integration into existing structures, ensuring ease of installation and retrofitting, thereby minimizing operational disruptions.Paragraph 6:Smooth Bar Grating's popularity has been further enhanced by its low maintenance requirements. Designed to withstand harsh operational conditions, it requires minimal cleaning and upkeep, reducing overall maintenance costs and increasing efficiency in industrial operations.Paragraph 7:Furthermore, Smooth Bar Grating is backed by [Company Name]'s extensive expertise and commitment to quality. The company utilizes state-of-the-art manufacturing processes and rigorous quality control measures to ensure that every grating product meets the highest industry standards. This dedication to excellence has earned [Company Name] a reputation for delivering reliable, durable, and high-performing industrial flooring solutions.Conclusion:Smooth Bar Grating, developed by [Company Name], is revolutionizing industrial applications by providing a durable, safe, and versatile flooring solution. Its innovative design, exceptional drainage, enhanced traction, and low maintenance requirements make it an ideal choice for various industries. As [Company Name] continues to push the boundaries of industrial flooring technology, Smooth Bar Grating is set to transform workplaces and offer value-added benefits to businesses worldwide.

Discover the Importance of Grating Weight Per M2 for Optimal Performance

Title: Innovative Grating Weight Per M2 Revolutionizes the IndustrySubtitle: Company Pioneers Lightweight Solution for Enhanced PerformanceIntroduction:In an industry-first development, a leading company has introduced an innovative grating weight per m2 solution aimed at revolutionizing industrial operations. By successfully removing excess weight without compromising strength or durability, this groundbreaking advancement promises to deliver significant benefits in various sectors. With a keen focus on customer needs and a commitment to technological innovation, this company continues to redefine standards within the grating industry.Product Overview:Unveiling their latest lightweight grating solution, the company's expert engineers have successfully developed a high-performance product that offers exceptional strength-to-weight ratio. Pioneering a manufacturing technique that maximizes strength through advanced materials and design, this groundbreaking grating product is set to transform industries reliant on structural integrity and load-bearing capacity.Key Features and Advantages:1. Unprecedented Weight Reduction: The company's grating weight per m2 reduces significantly in comparison to traditional alternatives available in the market. This weight reduction facilitates easier handling and installation, ultimately reducing labor costs and improving overall productivity.2. Robust Durability: While the grating weight per m2 is reduced, strength and durability remain uncompromised. The company employs cutting-edge materials and advanced engineering methodologies to guarantee a product that can withstand heavy loads, environmental stressors, and wear and tear, ensuring extended service life and enhanced safety.3. Anti-Corrosion Properties: The lightweight grating incorporates innovative corrosion-resistant properties, making it an ideal solution for sectors exposed to challenging environmental conditions such as marine, chemical, and oil and gas industries. This corrosion resistance increases the grating’s lifespan while reducing maintenance requirements and costs.4. Versatile Applications: The company's grating is designed to cater to a wide range of industries and applications. From industrial flooring, walkways, and mezzanines to drainage systems, trench covers, and safety barriers, this lightweight solution provides flexibility in design and functionality.Customer Testimonials:Industry professionals who have adopted the company's lightweight grating weight per m2 solution have expressed their satisfaction with the enhanced performance and reliability it provides. End users have praised the product's ease of handling during installation, as well as its ability to withstand rigorous usage and maintain optimum functionality over time. Many customers have reported substantial savings in labor costs, thanks to the reduced weight, while also praising its corrosion resistance and extended lifespan.Market Impact:This pioneering lightweight grating solution has the potential to significantly disrupt the grating industry by offering a superior alternative to conventional heavy weight grating systems. With its exceptional strength-to-weight ratio and anti-corrosion properties, it allows businesses in various sectors to optimize their operations while maintaining the highest standards of safety and reliability. The reduced grating weight per m2 not only enhances productivity but also reduces installation time and ongoing maintenance costs.Conclusion:By introducing this lightweight grating weight per m2 solution, the company has set a new industry benchmark, reflecting their commitment to innovation and customer-centric approach. This groundbreaking product has the potential to revolutionize multiple sectors, offering businesses a more efficient and cost-effective solution for their grating needs. With its combination of reduced weight, uncompromised strength, and versatile applications, this advancement is poised to reshape the way industries utilize grating systems on a global scale.

Discover the Versatility and Benefits of Open Floor Grating

Title: Innovative Open Floor Grating Revolutionizes Industrial Safety and EfficiencyIntroduction:In today's fast-paced industrial landscape, ensuring the safety and efficiency of operations has become paramount. That's where the groundbreaking Open Floor Grating, designed and manufactured by renowned industry leader {}, comes into play. This innovative grating solution has proven to be a game-changer, significantly enhancing workplace safety and streamlining industrial processes. With a commitment to excellence and a drive to revolutionize the industry, {} has introduced an unparalleled product that merits closer examination.The Open Floor Grating is a versatile flooring solution that offers numerous benefits across a wide range of industries. It provides exceptional stability, slip resistance, and durability, making it ideal for industrial manufacturing plants, oil refineries, chemical factories, and other high-risk environments. By replacing traditional concrete or other solid flooring options, this grating reduces the risk of accidents and injuries caused by slips, trips, and falls.One of the key advantages of the Open Floor Grating is its unique design, which allows for effective drainage of liquids and debris. This feature significantly reduces the risk of pooling or stagnant water, effectively mitigating the growth of bacteria and potential contamination in sensitive working environments. The grating's openness also facilitates superior air circulation, helping to maintain suitable temperature levels and prevent the accumulation of harmful gases.Moreover, the Open Floor Grating is made from high-quality materials that are resistant to corrosion, wear and tear, and extreme weather conditions. This ensures its longevity and minimizes the need for costly repairs or replacements. Additionally, the grating's modular design allows for easy installation, enabling businesses to optimize their operational efficiency while minimizing downtime.The incorporation of anti-slip technology in the Open Floor Grating is another noteworthy feature. Enhanced grip and traction ensure that employees can safely navigate the workspace, even in challenging conditions or when handling hazardous substances. By prioritizing safety, companies can reduce the occurrence of workplace accidents, protect their employees' well-being, and avoid potential legal liabilities.The benefits of the Open Floor Grating extend beyond safety considerations to overall operational efficiency. The grating's lightweight construction allows for easy removal and repositioning, making maintenance tasks more accessible and time-effective. This flexibility is especially valuable in industries where regularly inspecting machinery, equipment, or underlying infrastructure is necessary. Furthermore, the Open Floor Grating contributes to enhanced productivity by facilitating the efficient flow of machinery, materials, and personnel. Its open design eliminates unnecessary barriers and restrictions, reducing bottlenecks and preventing unnecessary detours. This optimization of movement within the workspace can boost productivity levels, ultimately leading to improved operational outcomes and competitiveness.In conclusion, {}'s Open Floor Grating represents a significant breakthrough in industrial safety and efficiency. By addressing the critical need for workplace safety while also enhancing overall operational efficiency, this innovative grating solution is transforming industrial environments across various sectors. With its exceptional durability, anti-slip properties, and versatility, the Open Floor Grating is undeniably a powerful tool for forward-thinking organizations striving for excellence in safety, productivity, and profitability.Note: This response has been generated by OpenAI's GPT-3 language model. While it strives to provide accurate and timely information, it is recommended to verify the details and make any modifications as needed.

Discover the Benefits of a Galvanised Drain Grate for Effective Drainage

Title: Innovative Galvanized Drain Grate Revolutionizes Drainage SystemsIntroduction:In the world of urban infrastructure, proper drainage systems play a crucial role in preventing floods, water-related accidents, and road damage. To enhance the effectiveness of such systems, Company XYZ has introduced an innovative Galvanized Drain Grate. This revolutionary product aims to address major challenges faced by municipalities, businesses, and homeowners, providing a higher level of safety and functionality. With its unique design and robust construction, the Galvanized Drain Grate promises to revolutionize drainage systems across a wide range of applications.Body:1. The Importance of Effective Drainage Systems (100 words)Efficient drainage systems are vital to managing stormwater and preventing various issues caused by flooding, such as infrastructure damage and accidents. Poorly designed or outdated drainage solutions often fail to meet modern requirements, leading to catastrophic consequences. Recognizing the need for improved drainage solutions, Company XYZ has developed a Galvanized Drain Grate that promises advanced functionality and durability.2. The Features and Benefits of the Galvanized Drain Grate (150 words)The Galvanized Drain Grate is manufactured using state-of-the-art galvanization techniques, which significantly enhance its strength and longevity. The galvanization process ensures that the grates are resistant to corrosion, rust, and extreme weather conditions, making them suitable for both urban and coastal environments.Furthermore, the unique design of the drain grate optimizes water flow, improving overall drainage efficiency. The grate's openings are engineered to prevent debris accumulation, minimizing the risk of clogging and the need for frequent maintenance. It is also equipped with anti-slip features, ensuring the safety of pedestrians and vehicles.3. Applications in Various Settings (150 words)The Galvanized Drain Grate is versatile and can be utilized in a wide range of settings. Its strength and durability make it ideal for use in high-traffic areas, such as busy city streets, highways, parking lots, and industrial zones. Additionally, it can be installed in residential areas, preventing water buildup and potential hazards during heavy rainfalls.Furthermore, the Galvanized Drain Grate's ability to resist rust and corrosion makes it suitable for coastal regions, where saltwater can cause rapid deterioration of conventional grates. By harnessing the power of galvanization, this product extends its application potential to areas that have traditionally struggled with maintaining effective drainage.4. Environmental Considerations (100 words)In this era of growing environmental consciousness, selecting products that are eco-friendly is of paramount importance. The Galvanized Drain Grate stands out as an environmentally responsible choice due to its long lifespan and resistance to degradation. By minimizing the need for frequent replacement and reducing the generation of waste, the drain grate proves to be a sustainable solution, aligning with the principles of a circular economy.5. Collaboration with Cities and Infrastructure Developers (200 words)Company XYZ has been actively collaborating with municipalities, urban planners, and infrastructure developers to provide customized Galvanized Drain Grate solutions that meet specific requirements. By working closely with these stakeholders, the company ensures that the drain grates are seamlessly integrated into existing and future infrastructure. This collaborative approach also allows for the identification of potential challenges and the incorporation of necessary modifications.Additionally, Company XYZ provides comprehensive post-installation support, including ongoing maintenance and monitoring. This ensures that the benefits of the Galvanized Drain Grate are sustained in the long run and that drainage systems continue to operate optimally.Conclusion:With its innovative design, enhanced durability, and versatility, the Galvanized Drain Grate from Company XYZ represents a significant advancement in drainage system technology. By providing improved functionality, increased safety, and reduced maintenance needs, this product has the potential to transform drainage systems globally. With a commitment to sustainability and a focus on collaborations with various stakeholders, Company XYZ is poised to contribute to the development of more efficient and effective urban infrastructure.

Discover the Latest Updates on Galvanized Metal Grating and its Benefits

Title: Galvanized Metal Grating Industry Gains Traction with Innovative Solutions from Leading ProviderIntroduction:In the fast-paced industrial sector, Galvanized Metal Grating has emerged as a versatile and essential solution for various applications. Galvanized Metal Grating, provided by a leading company (need to remove brand name), has gained significant popularity due to its robustness, durability, and cost-effectiveness. With a wide range of applications across industries, this innovative product has revolutionized the safety and efficiency standards for workers, offering a reliable platform for heavy-duty operations.Body:1. Overview of Galvanized Metal Grating:Galvanized Metal Grating has become a go-to solution for industries that require durable and reliable platforms for several applications. Made from galvanized steel, this type of grating offers exceptional strength, corrosion resistance, and a superior load-bearing capacity, making it suitable for heavy industrial use. The galvanization process involves coating the grating with a layer of zinc, which enhances its longevity and resistance to rust and other environmental elements.2. Applications:2.1 Industrial Sector:Galvanized Metal Grating finds extensive applications in the industrial sector, particularly in manufacturing plants, warehouses, refineries, and power plants. It provides a secure walking surface in areas prone to slippery conditions, preventing accidents and ensuring worker safety. Its load-bearing capacity enables the grating to withstand the weight of heavy machinery, facilitating a smoother workflow and increasing operational efficiency.2.2 Construction Industry:The construction industry greatly benefits from galvanized metal grating due to its ability to handle heavy loads and its corrosion-resistant properties. It is commonly used in construction sites as scaffolding platforms, walkways, and stair treads. Its high strength-to-weight ratio also adds an extra layer of safety in high-rise building projects.2.3 Transportation Sector:Galvanized Metal Grating plays a crucial role in the transportation sector. It is widely utilized for the construction of pedestrian bridges, highway safety barriers, and platforms for railway stations and airports. The grating's design allows for efficient drainage, eliminating the accumulation of rainwater, snow, or debris, thus reducing the risk of accidents.3. Market Demand and Growth:The growing demand for Galvanized Metal Grating can be attributed to the ease of customization, cost-effectiveness, and its ability to meet stringent safety standards. Industries across the globe are recognizing the long-term benefits of investing in durable and reliable grating solutions. The market for galvanized metal grating is projected to witness substantial growth in the coming years, driven by infrastructure development, industrial expansion, and stringent safety regulations.4. Leading Provider:The (brand name removed) is a pioneering provider of Galvanized Metal Grating solutions, renowned for its commitment to product excellence and customer satisfaction. With years of experience in the industry, they have established themselves as a trusted partner for businesses seeking top-quality grating solutions. The company's extensive range of galvanized metal grating products, coupled with advanced customization options, ensures that they cater to a wide array of industry-specific requirements.5. Key Features and Advantages:5.1 Strength and Durability:Galvanized Metal Grating, provided by (brand name removed), offers exceptional strength and durability, capable of withstanding heavy loads and extreme weather conditions. The galvanized coating provides an additional layer of protection against corrosion, extending the product's lifespan.5.2 Versatility:The comprehensive range of Galvanized Metal Grating is available in various sizes, designs, and configurations, ensuring suitability for diverse industry applications. It can be custom-designed to match specific project requirements, offering enhanced flexibility to clients.5.3 Easy Installation and Maintenance:The grating's unique design enables easy installation, reducing downtime and labor costs. Additionally, the galvanized coating requires minimal maintenance, making it a cost-effective solution in the long run.6. Commitment to Sustainability:Apart from its exceptional performance characteristics, Galvanized Metal Grating aligns with sustainability goals. The grating's galvanized coating is environmentally friendly, as it requires minimal energy during production and offers recyclability at the end of its lifecycle, thereby reducing the overall carbon footprint.Conclusion:The Galvanized Metal Grating industry, spearheaded by the pioneering solutions provided by (brand name removed), continues to gain significant traction. Its robustness, durability, and cost-effectiveness have made it an indispensable component across various industries. As the importance of safety and efficiency increases, Galvanized Metal Grating stands as a reliable and innovative solution that caters to the evolving needs of the industrial sector.

Top-rated Galvanized Metal Grating: Perfect Solution for All Your Needs

Galvanized Metal Grating Revolutionizes Industrial Safety and Efficiency(Attention: Brand name has been removed)In today's fast-paced world, industries across the globe are constantly seeking innovative solutions to enhance safety standards and maximize productivity. One such groundbreaking product that is transforming the industrial landscape is Galvanized Metal Grating. This remarkable material has become a game-changer for multiple industries, ensuring worker safety, optimizing operations, and providing long-lasting durability.Galvanized Metal Grating, developed by an industry leader (Company name: ), is a superior flooring solution that has revolutionized the way industrial spaces function. Made from galvanized steel, this grating consists of parallel spaced bars, combined with perpendicular, cross bars, creating an interlocking arrangement. This unique design allows for the efficient flow of air, light, and fluids, making it a suitable choice for various applications.The primary advantage of Galvanized Metal Grating lies in its exceptional resilience and durability. By undergoing the galvanization process, the grating receives a protective zinc coating, which shields it from corrosion, rust, and wear. This feature ensures longevity and significantly reduces maintenance costs, making it a cost-effective choice for any industrial setting. The grating's robust construction can withstand heavy loads and high-traffic areas, providing a safe working environment for employees.Worker safety is paramount in any industry, and Galvanized Metal Grating delivers on this front. The unique pattern of the grating bars offers an anti-slip surface, minimizing the risk of accidents caused by slippery flooring. This feature, combined with its high load-bearing capacity, makes it ideal for walkways, platforms, stair treads, and other areas where slip-resistance and stability are essential.Health and safety regulations vary across industries, and Galvanized Metal Grating caters to these requirements with ease. Whether it is a manufacturing plant, oil refinery, wastewater treatment facility, or any other industry, this versatile grating can be customized to meet specific needs. With options for varying bar spacing, load capacities, and surface profiles, it provides tailored solutions to ensure compliance with stringent safety guidelines.Additionally, the open structure of Galvanized Metal Grating allows for efficient drainage, making it particularly well-suited for wet or hazardous environments. Rainwater, oil spills, and other fluids can quickly pass through the grating, minimizing the risks associated with standing water or slippery surfaces. This not only enhances safety but also promotes a clean and hygienic working environment.Moreover, the distinct design of Galvanized Metal Grating allows for ample circulation of air and natural light. This feature provides ventilation, reducing the accumulation of fumes, heat, and humidity. With improved air quality, employees can work comfortably, enhancing productivity and overall well-being.Galvanized Metal Grating has gained recognition globally, thanks to its unmatched quality and reliability. The product adheres to international standards, ensuring consistency and uniformity across all applications. Its versatility extends beyond safety applications, as it is also commonly used in architectural and aesthetic projects, adding an industrial touch to contemporary designs.As industries strive for sustainability and eco-friendliness, Galvanized Metal Grating steps up to the challenge. Manufacturing the grating from recycled materials and the galvanization process itself being environmentally friendly, it is a conscientious choice for those aiming to reduce their carbon footprint.In conclusion, Galvanized Metal Grating has established itself as a revolutionary solution within the industrial sector. Its exceptional durability, slip-resistance, drainage capabilities, and compliance with safety regulations make it the preferred choice for numerous industries. With its valuable features, this grating system combines safety, efficiency, and sustainability, transforming the industrial landscape for the better.

Mild Steel Grating: A Comprehensive Guide to Its Features, Uses, and Applications

Title: The Rising Demand for Mild Steel Grating in the Construction IndustryIntroduction:In recent years, the construction industry has experienced remarkable growth, with a surge in infrastructure projects across the globe. One crucial element in constructing safe and durable structures is the installation of high-quality grating systems. This news article aims to shed light on the increasing demand for mild steel grating and its vital role in the construction industry.The Rise of Infrastructure Projects:Infrastructure development is a key driver of economic growth, aiding countries in improving connectivity, transportation, and promoting overall development. To meet this growing demand, construction companies are looking for reliable and cost-effective materials. Among these materials, mild steel grating has emerged as a popular choice due to its versatility, durability, and excellent load-bearing capabilities.Key Characteristics of Mild Steel Grating:Mild steel grating, fabricated from low-carbon steel, is highly preferred for its exceptional strength-to-weight ratio. It is known for its longer lifespan compared to other grating materials, making it a cost-effective option for builders and engineers. The grating is available in various sizes and designs to cater to different construction projects, ranging from walkways and platforms to staircases and drainage systems.Versatility in Construction Projects:Mild steel grating finds applications in a wide range of construction projects. Its corrosion-resistant properties make it suitable for outdoor installations, including footbridges, parking lots, and industrial platforms. Additionally, its anti-slip surface enhances safety measures on walkways, ramps, and staircases, preventing accidents in high-traffic areas.Growing Concern for Safety:The construction industry recognizes the importance of prioritizing safety measures. Mild steel grating plays a crucial role in ensuring structural integrity and preventing accidents. Its robust design can withstand heavy loads, making it suitable for vehicular and pedestrian applications. By providing a secure platform, mild steel grating contributes to the overall safety and longevity of the structures.Environmental Sustainability:The demand for sustainable construction practices has driven the adoption of environmentally friendly building materials. Mild steel grating aligns with these objectives, as it is recyclable and requires minimal maintenance. Its eco-friendly attributes make it an attractive choice for environmentally conscious builders, contributing to the reduction of the industry's carbon footprint.Advancements in Manufacturing Techniques:The manufacturing sector constantly strives to improve production techniques, resulting in a significant growth in the quality of mild steel grating. Advanced manufacturing processes, such as laser cutting and precision welding, ensure high precision and consistency in the fabrication of grating systems. These technological advancements have further cemented mild steel grating's position as a preferred choice for construction projects.Expanding Market Opportunities:With the rapid urbanization witnessed globally, the demand for mild steel grating is expected to soar in the coming years. Developing countries, especially those with a burgeoning infrastructure sector, provide lucrative market opportunities for manufacturers and suppliers of mild steel grating. The adoption of favorable government policies aimed at attracting foreign investments in the construction industry further bolsters the market growth.Company Introduction:{} is a prominent manufacturer and supplier of mild steel grating, catering to both domestic and international markets. With an unwavering commitment to quality and customer satisfaction, the company has carved a niche for itself in the industry. Its state-of-the-art manufacturing facility, equipped with the latest technology, ensures the production of premium-grade mild steel grating systems. Through continuous research and development, the company strives to provide innovative solutions that meet the ever-evolving needs of the construction industry.Conclusion:Mild steel grating has become an integral component of construction projects, owing to its superior strength, durability, and safety features. With the construction industry witnessing continued growth on a global scale, manufacturers like {} are expected to play a pivotal role in meeting the increasing demand for high-quality grating systems. As urbanization persists and infrastructure requirements escalate, mild steel grating will continue to be a vital pillar in the construction industry's pursuit of building safe and sustainable structures.

Discover the Efficiency and Versatility of Grating 30x3

Title: Groundbreaking Innovation in Grating Technology Revolutionizes Industrial SolutionsIntroduction: Gratings have long been an indispensable component in various industrial sectors, providing essential solutions for safety, efficiency, and structural integrity. One company, with its strong commitment to innovation and cutting-edge technologies, has recently introduced a ground-breaking product – the 30x3 Grating. This revolutionary system is set to transform a wide range of industrial applications, offering superior functionality, durability, and versatility.Body:1. Industry Challenges and the Need for Innovation:The industrial sector has always faced challenges in ensuring the safety and stability of structures while optimizing operational efficiency. Traditional gratings have often fallen short in meeting these requirements due to limitations in their design and material composition. Recognizing the need for an advanced grating solution, Company XYZ has developed the 30x3 Grating to address these challenges effectively.2. Unveiling the 30x3 Grating:The 30x3 Grating represents a breakthrough in grating technology. It is designed using state-of-the-art materials and manufacturing methods, resulting in a product that surpasses conventional gratings in strength, durability, and versatility. With a unique composition that combines precision-engineered steel and advanced corrosion-resistant coatings, the 30x3 Grating is built to withstand the harshest environments, including heavy-duty engineering, offshore drilling, mining operations, and wastewater treatment plants.3. Strength and Load-Bearing Capacity:The 30x3 Grating boasts exceptional load-bearing capabilities, enabling it to support heavy machinery and withstand substantial mechanical forces. Its innovative design ensures maximum grip, preventing slippage and reducing the risk of accidents in industrial settings. The grating's enhanced structural integrity contributes to the overall stability of infrastructure, making it an ideal choice for construction projects such as platforms, walkways, ramps, and stair treads.4. Durability and Longevity:Prolonged exposure to extreme weather conditions, chemicals, and constant foot traffic can significantly affect the lifespan of traditional gratings. However, the 30x3 Grating's corrosion-resistant coating surpasses industry standards, providing outstanding protection against rust, corrosion, and abrasion. This unique feature significantly extends the grating's lifespan, reducing the need for frequent replacements and maintenance, leading to cost savings for companies across various industries.5. Versatility and Customization:Recognizing that every industrial project has unique requirements, Company XYZ offers customization options for the 30x3 Grating. Clients can choose from various surface textures, mesh patterns, and sizes, ensuring a perfect fit for their specific needs. This flexibility allows for seamless integration into diverse industrial applications, including oil and gas facilities, manufacturing plants, transportation infrastructure, and commercial buildings.6. Commitment to Sustainability:Company XYZ is dedicated to sustainability and environmental stewardship. The 30x3 Grating's superior durability minimizes the waste generated through frequent replacements, aligning with the principles of a circular economy. Additionally, the grating's manufacturing process utilizes eco-friendly production techniques and materials, ensuring minimal carbon footprint throughout its lifecycle.7. Future Prospects and Market Impact:The introduction of the 30x3 Grating represents a significant advancement in the grating industry, with the potential to disrupt traditional market dynamics. Its superior performance and longevity are expected to attract numerous industries seeking reliable, cost-effective, and high-performance solutions. As the demand for infrastructure development and industrial expansion continues to rise, the 30x3 Grating has positioned Company XYZ as a trailblazer in the industry, promoting increased efficiency, safety, and sustainability.Conclusion:The 30x3 Grating has revolutionized the industrial sector, challenging traditional grating solutions with its unrivaled strength, durability, and versatility. With its exceptional load-bearing capacity, corrosion resistance, and customization options, this innovative product has proven to be a game-changer in multiple industries. Company XYZ's commitment to sustainability further reinforces the grating's value proposition, setting new standards for safety, efficiency, and environmental consciousness. As industrial projects continue to evolve, the 30x3 Grating propels the industry into a new era of robust and sustainable infrastructure solutions.